The introduction of

The Honicel aluminium honeycomb Panel -HP-

The market regularly asked Honicel whether, based on its unique approximately 75 years of expertise in the field of honeycomb technology, Honicel could produce an ultra- lightweight, extremely strong, “all circumstances-proof”, durable, thin panel and supply it to its customers in the market for their further application or processing. The wish / demand was, that this ultra-lightweight panel should be: moisture- / waterproof, fireproof, insect- proof as well as fungus- / rot-proof. Next request was that the panel should be very easy to process.

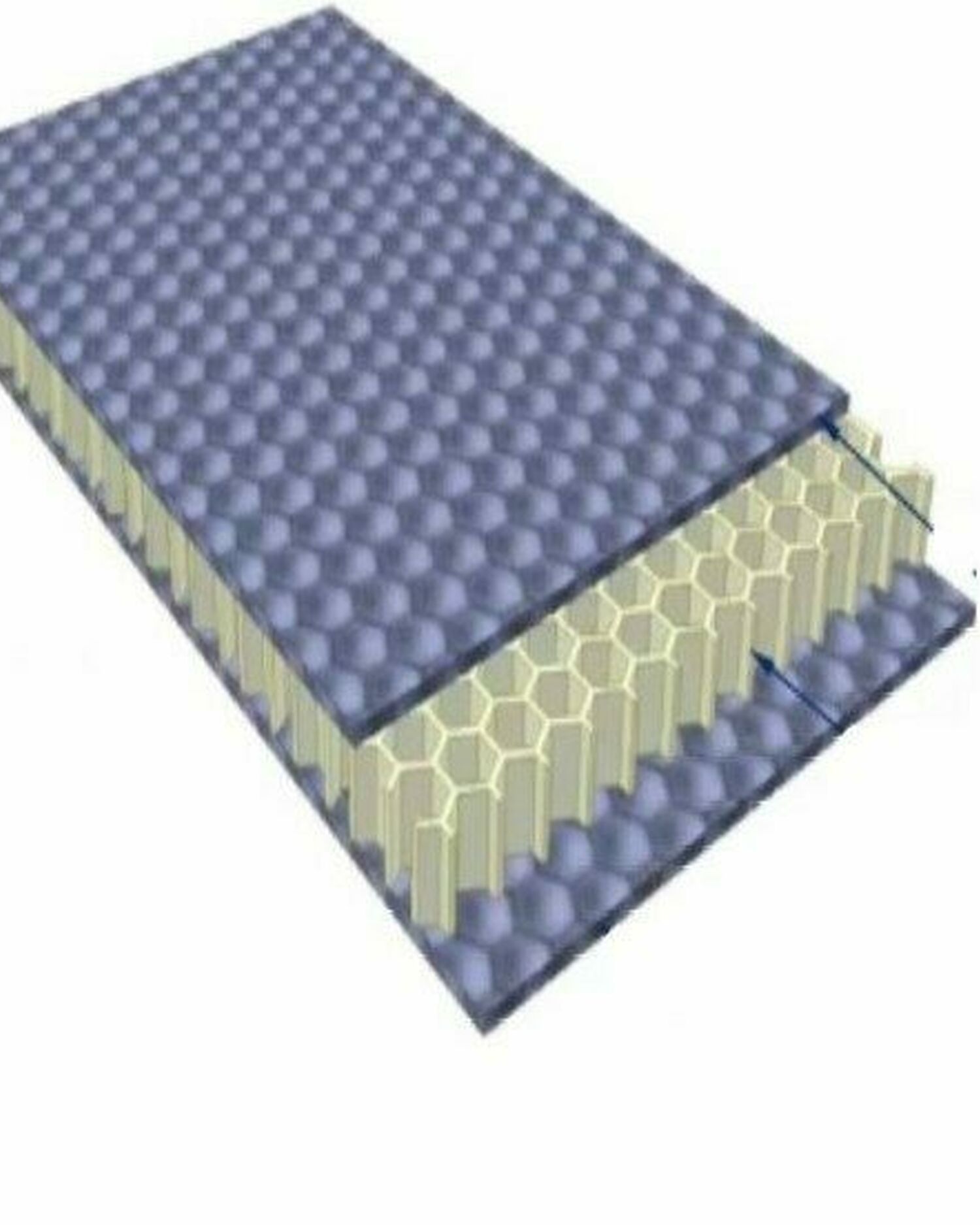

Bearing all these wishes and requirements in mind, the Honicel Research & Development Team has developed the PU-injected Glass Fibre Panel with a Aluminium Honicel- honeycomb core Sandwich Panel. Called in short, the Honicel aluminium honeycomb Panel, shortcut, the HP.